An Introduction to Aluminum Electrolytic Capacitors

Capacitors. So many different types and technologies… but why? What’s unique about them? This blog post attempt to answer those questions about one of the most common capacitor technologies: the aluminum electrolytic capacitor.

The aluminum electrolytic capacitor is a passive component that has traditionally been used for filtering, timing networks, by-pass, coupling and other applications requiring a cost effective, volumetrically efficient and highly reliable component.

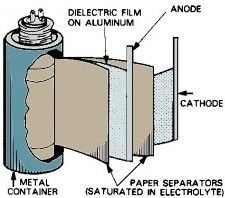

An aluminum electrolytic capacitor consists of an anode foil, a cathode foil and separator paper which are wound together and impregnated with an electrolyte. The anode foil has an aluminum oxide layer acting as the dielectric. After the thin aluminum foil (65 to 100 microns) is electrochemically etched to increase the plate’s surface area, the dielectric is produced by anodic oxidation on its surface. The cathode foil, in general, utilizes no oxidation process.

Note that due to the physical design elements and construction, not only does a capacitor have capacitance, but it also has a series resistance and inductance as well as a parallel resistance allowing the flow of current.

The capacitance of aluminum electrolytic capacitors (in microfarads) is expressed by the following equation:

C = 8.855 x 10e-6 x (ES/d)

E = Dielectric constant

S = Surface area of dielectric (cm2)

d = Thickness of the dielectric (cm)

Large capacitance can be obtained when:

- the dielectric constant is high

- the surface area is large

- the dielectric is thin

In aluminum electrolytic capacitors the dielectric constant is only 8 to 10, but the aluminum oxide dielectric layer is extremely thin (about 15 Angstroms per volt). High gain foil produced by the electrochemical etching creates a surface magnification, or gain, as much as 100 times for low voltage foil and 20 to 25 times for high voltage foil. Therefore (and this is a critical benefit of these capacitors):

An aluminum electrolytic capacitor can provide a large capacitance compared to other types of capacitors of the same volume.

Nippon Chemi-Con – the parent company of United Chemi-Con – is the world’s largest manufacturer of aluminum electrolytic capacitors. NCC pioneered the development of raw material processing techniques and highly automated production systems. The product improvements of these innovations have dramatically improved circuit design flexibility and led to many new applications for aluminum electrolytic capacitors.